Visitors to the Mutter Museum can also see the "Soap Woman". She may have died sometime in the 19th century. Certain chemicals present in the soil she was buried in turned her into soap, literally

In 1874, the autopsy of Siamese Twins Chang and Eng Bunker (the first set of Siamese, or conjoined, twins) was performed in the museum. The twins' connected livers, as well as a plaster cast of their bodies, has been on display ever since.

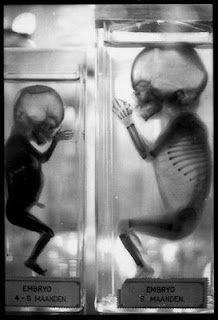

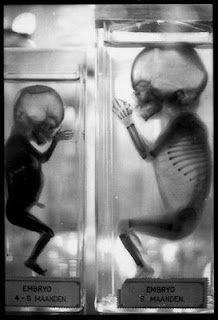

Other specimens include a preserved 5 foot long human colon, preserved human fetuses, and part of the brain of President Garfield's assassin, Charles Guiteau. The Mutter Museum is also widely know for it's collection of skulls, as well as a collection of 2,000 objects people have swallowed.

It's a museum of medical oddities. They have many exhibits of conjoined twins... It's extremely disturbing

The Mutter Museum's collection now has over 20,000 artifacts. The artifacts include fluid-preserved specimens, skeletal specimens, medical instruments, models, and much more

d machines, although recently more producers have gone to 8-head machines to drive down bottle costs. It is estimated that over 2500 reciprocating screw blow molding machines for production of HDPE containers have been delivered in the United States - and over 3200 worldwide.

d machines, although recently more producers have gone to 8-head machines to drive down bottle costs. It is estimated that over 2500 reciprocating screw blow molding machines for production of HDPE containers have been delivered in the United States - and over 3200 worldwide.